Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

In the world of mechanical systems, two popular concepts are chain drives and belt drives. Choosing between them can lead to significant differences in performance and efficiency. This article explores various aspects of chain drive vs belt drive to help you make an informed decision.

A chain drive consists of interconnected links that connect two or more gears. This system provides a direct transfer of power from one gear to another, ensuring efficient and precise motion transmission. Chain drives are known for their durability and ability to handle high loads and speeds.

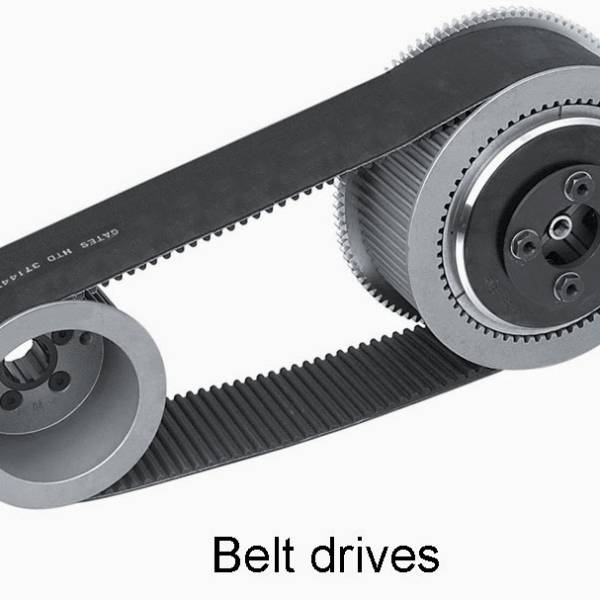

In contrast, a belt drive uses a looped belt that fits over pulleys to transmit power. This system relies on friction between the belt and the pulleys for power transfer. Belt drives are typically quieter and require less maintenance compared to chain drives. Understanding these definitions helps in comparing the two systems and choosing the appropriate one based on specific needs and applications.

When examining efficiency, chain drives often excel in performance. They have lower energy losses because they face less friction. As a result, they offer better energy transmission and reduced wear over time. Chain drives work well in demanding applications where high torque is required. They handle heavy loads effectively due to their strong, interlocking design. This efficiency makes them a preferred choice for high-performance machinery.

In contrast, belt drives tend to lose energy due to slippage. This inefficiency becomes apparent in applications requiring substantial torque. However, belt drives can manage lighter loads with considerable effectiveness. They offer a quieter operation and are generally easier to install. Despite their lower efficiency in high-torque scenarios, they remain valuable in systems where noise reduction and cost are important. Thus, choosing between chain and belt drives depends on the specific needs of the application.

In terms of maintenance, chain drives typically require more attention. They need regular lubrication to function effectively and avoid excessive wear. Over time, chains can stretch and require periodic adjustments to maintain proper tension. This frequent upkeep ensures optimal performance and longevity. Chain drives also necessitate inspections to check for wear and tear, making them a more hands-on option.

On the other hand, belt drives generally demand less maintenance. They do not require lubrication, which simplifies upkeep considerably. Additionally, belts show minimal wear under normal conditions. However, they can degrade more quickly under extreme conditions such as high temperatures or heavy loads. Thus, while belt drives offer easier maintenance, it’s essential to consider their performance limits and environmental factors when choosing between chain and belt systems.

Noise levels significantly influence application choices. Chain drives, with their metallic links and high tension, generate considerable noise. This characteristic can be a drawback in environments where silence is crucial. On the other hand, belt drives, made of rubber, absorb sound effectively. They provide a quieter operation, enhancing the acoustic comfort in any setting. Therefore, when noise reduction is a priority, belt drives present a superior alternative.

In scenarios where noise is a critical factor, belt drives stand out. Their rubber composition not only absorbs sound but also reduces vibrations. This feature makes them ideal for applications requiring a tranquil operation. Conversely, chain drives, with their inherent noise production, may not be suitable for such environments. The decision between chain and belt drives, thus, hinges on the noise tolerance of the application. For a peaceful operation, belt drives are the clear choice.

Cost-effectiveness is key when choosing between chain and belt drives. Chain drives, despite their higher initial material costs, offer durability that can justify the investment. Their robustness means less frequent replacements, which can balance the initial expense. Conversely, belt drives are more affordable to install initially. However, their shorter lifespan may necessitate more replacements over time. This could negate any initial cost savings. Thus, a comprehensive cost analysis is essential, considering both short-term and long-term financial implications.

In the financial comparison, chain drives may seem pricier upfront. Yet, their longevity can lead to cost savings in the long run. They require less maintenance and fewer replacements, which can be a significant financial advantage. Meanwhile, belt drives, though cheaper to install, may demand more frequent replacements. This recurring cost can accumulate, potentially surpassing the initial savings. When considering options like an orthopedic belt for back pain for females, evaluating both initial costs and long-term benefits is essential for making a wise investment. Therefore, when deciding between the two systems, it’s crucial to factor in both the immediate and ongoing costs. This balanced approach ensures a financially sound decision.

The choice between chain and belt drives hinges on the application’s demands. Chain drives, known for their strength, thrive in heavy-duty tasks. They are commonly found in motorcycles and industrial machinery. Their ability to handle high torque makes them suitable for demanding environments. In contrast, belt drives are better suited for lighter applications. They perform optimally in HVAC systems and similar settings. These drives are ideal for low-torque and moderate-speed operations. Therefore, the nature of the task at hand should guide your decision.

Understanding the suitability of each drive for specific applications is crucial. Chain drives, with their robust construction, are perfect for high-torque scenarios. They provide reliable performance in tough conditions. Belt drives, on the other hand, shine in applications requiring less torque and speed. Their flexibility and quiet operation make them a good fit for less strenuous tasks. By considering the application’s requirements, one can make an informed choice between chain and belt drives. This approach ensures that the selected drive system meets the operational needs effectively. Proper belt sizing is essential to maximize performance in applications suited for belt drives, ensuring efficiency and longevity in less strenuous tasks.

When deciding between chain and belt drives, consider their distinct advantages and disadvantages. Chain drives are durable and perform well under heavy loads. However, they necessitate regular maintenance to ensure optimal operation. Belt drives, conversely, operate quietly and are more cost-effective. When choosing a garage door opener belt, consider its quiet operation and cost-effectiveness, particularly if you prioritize minimal maintenance and noise levels. Yet, they may lack the longevity and strength of chain drives. It’s essential to evaluate your specific needs, such as efficiency, maintenance requirements, noise levels, and the nature of the application. By doing so, you can make a choice that best suits your situation.

Understanding the characteristics of both systems is crucial for making an informed decision. Chain drives are ideal for applications requiring high torque and durability. They are less suitable for environments where noise is a concern or where maintenance is infrequent. Belt drives, with their quiet operation and lower cost, are perfect for lighter tasks. However, they may not withstand the rigors of heavy-duty applications. By prioritizing your requirements and analyzing the conditions, you can confidently choose between chain and belt drives. This careful consideration ensures that your decision is aligned with your operational goals and conditions.